Digital Twins: 25% Operational Savings for US Industries by 2025

The adoption of digital twins is projected to deliver a remarkable 25% in operational savings for U.S. industries by 2025, primarily through advanced virtual prototyping and enhanced efficiency.

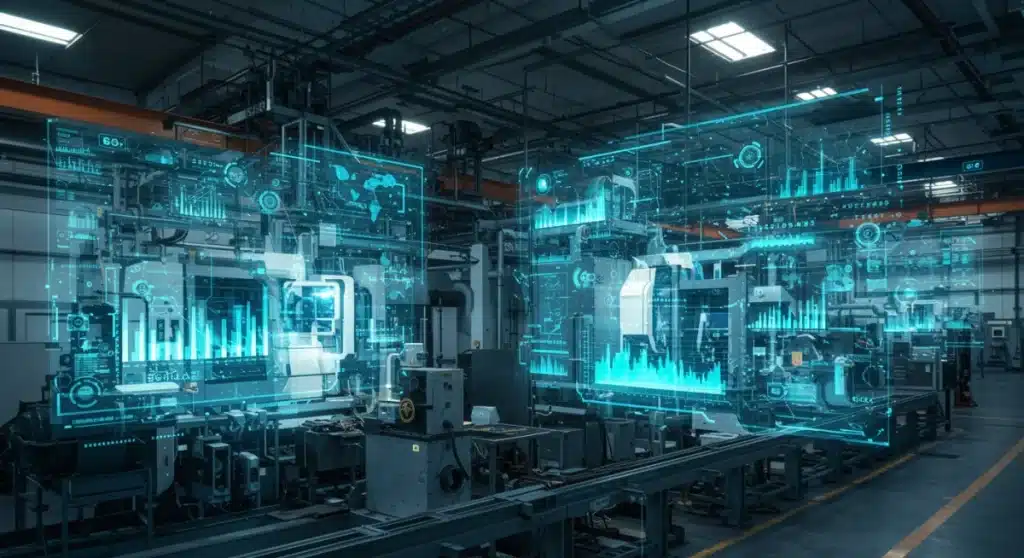

Digital Twins: Unlocking 25% Operational Savings for U.S. Industries by 2025 Through Virtual Prototyping (FINANCIAL IMPACT, COMPARISON/ANALYSIS) is more than a technological trend; it’s a strategic imperative reshaping the industrial landscape. This immediate financial impact, driven by virtual prototyping, signals a pivotal shift in how U.S. businesses approach efficiency, cost reduction, and innovation. We examine the latest developments, what they mean for various sectors, and the tangible benefits currently unfolding.

The Rise of Digital Twins in U.S. Industry

The concept of a digital twin, a virtual replica of a physical asset, process, or system, has rapidly evolved from theoretical possibility to practical necessity. U.S. industries, from manufacturing to energy, are increasingly recognizing its potential to revolutionize operations. This technology allows for real-time monitoring, predictive analysis, and virtual experimentation, all contributing to substantial efficiency gains.

The market for digital twin technology is expanding at an unprecedented rate, with projections indicating significant growth in investment and implementation. This surge is not merely about adopting new tech but about fundamentally rethinking operational frameworks to achieve greater agility and resilience. Early adopters are already reporting measurable improvements in various key performance indicators.

What defines a digital twin?

- Virtual Representation: A digital model that mirrors a physical object or system.

- Real-time Data Integration: Continuously updated with data from sensors on its physical counterpart.

- Predictive Analytics: Uses historical and real-time data to forecast future performance and potential issues.

- Simulation and Optimization: Allows for testing scenarios and optimizing processes virtually before physical implementation.

The core value proposition of digital twins lies in their ability to provide actionable insights. By creating a dynamic link between the physical and digital worlds, companies can identify inefficiencies, predict failures, and test modifications without disrupting actual operations, leading directly to reduced costs and improved output.

Unlocking Operational Savings through Virtual Prototyping

Virtual prototyping, powered by digital twin technology, is a game-changer for reducing development cycles and associated costs. Instead of building multiple physical prototypes, companies can iterate and refine designs in a virtual environment, saving significant time and material expenses. This capability is a primary driver behind the projected 25% operational savings for U.S. industries.

The traditional prototyping process is often lengthy, expensive, and resource-intensive. Each physical iteration requires materials, labor, and testing, all of which contribute to the final product cost. Digital twins bypass many of these hurdles, enabling rapid design changes and immediate feedback, which accelerates time-to-market and enhances product quality.

Accelerated product development

With virtual prototyping, design flaws can be identified and corrected early in the development phase, drastically reducing the need for costly physical rework. This iterative digital process ensures that by the time a physical prototype is created, it is already highly optimized, minimizing expenditure and speeding up the entire product lifecycle. The precision offered by digital twins in predicting performance and identifying potential issues is unmatched by conventional methods.

Furthermore, the ability to simulate various operational conditions and user scenarios in a virtual space allows for a more comprehensive understanding of a product’s behavior before it even reaches production. This foresight translates into superior product design and fewer post-launch issues, solidifying the financial benefits of digital twin operational savings.

Financial Impact Across Key U.S. Sectors

The financial ramifications of digital twin adoption are profound and widespread, touching critical U.S. industries such as manufacturing, aerospace, energy, and healthcare. Each sector stands to gain substantial benefits, contributing to the overarching goal of 25% operational savings by 2025. This impact is not uniform but tailored to the specific challenges and opportunities within each industry.

In manufacturing, for example, digital twins enable predictive maintenance, reducing unexpected downtime and extending the lifespan of machinery. This proactive approach to asset management can save millions in repair costs and lost production. For aerospace, virtual prototyping allows for rigorous testing of aircraft components and systems under extreme conditions, ensuring safety and optimizing performance before a single physical part is manufactured.

Manufacturing efficiency gains

The manufacturing sector is perhaps the most immediate beneficiary of digital twin operational savings. By creating digital replicas of entire production lines, manufacturers can identify bottlenecks, optimize workflows, and even simulate the impact of new equipment or process changes. This leads to higher throughput, reduced waste, and significant cost reductions.

- Predictive Maintenance: Anticipating equipment failure before it occurs, minimizing unplanned downtime.

- Process Optimization: Fine-tuning production lines for maximum efficiency and reduced energy consumption.

- Supply Chain Resilience: Simulating supply chain disruptions to build more robust and responsive networks.

The ability to run ‘what-if’ scenarios in a digital environment provides manufacturers with an unparalleled level of control and insight, allowing them to make data-driven decisions that directly impact their bottom line. This strategic advantage is crucial in today’s competitive global market.

Comparative Analysis: Digital Twins vs. Traditional Methods

A direct comparison between digital twin implementation and traditional operational methods clearly illustrates why the former is gaining such rapid traction. The benefits extend beyond mere cost reduction to encompass improved decision-making, enhanced innovation, and greater overall business agility. The stark contrast in outcomes highlights the transformative power of digital twin technology.

Traditional methods often rely on historical data, manual inspections, and reactive maintenance strategies. This approach can lead to unforeseen issues, extended downtimes, and higher operational costs. Digital twins, conversely, offer a proactive, data-driven methodology that anticipates problems and optimizes performance continuously, driving significant digital twin operational savings.

Key advantages of digital twins

- Cost Reduction: Significantly lowers expenses associated with prototyping, maintenance, and operational inefficiencies.

- Faster Time-to-Market: Accelerates product development and deployment cycles.

- Enhanced Quality: Improves product and process quality through rigorous virtual testing and optimization.

- Improved Decision-Making: Provides real-time data and insights for informed strategic and operational decisions.

While the initial investment in digital twin technology can be substantial, the long-term returns in financial savings, efficiency gains, and competitive advantage far outweigh the upfront costs. This makes digital twins a compelling choice for U.S. industries aiming to stay ahead.

Challenges and Considerations for Widespread Adoption

Despite the immense potential for digital twin operational savings, several challenges and considerations must be addressed for widespread adoption across U.S. industries. These include data integration complexities, cybersecurity concerns, the need for skilled talent, and the initial investment required for implementation. Overcoming these hurdles is crucial for realizing the full benefits of this transformative technology.

Integrating data from various sources, often disparate legacy systems, can be a complex undertaking. Ensuring data consistency, accuracy, and real-time flow is paramount for an effective digital twin. Furthermore, the sensitive nature of operational data necessitates robust cybersecurity measures to protect against breaches and unauthorized access. The industry is actively working on developing standardized protocols and secure platforms to address these issues.

Overcoming implementation barriers

The scarcity of professionals skilled in digital twin technology, data science, and advanced analytics poses another significant challenge. Companies must invest in training their existing workforce or recruit new talent capable of designing, implementing, and managing digital twin ecosystems. Educational institutions and industry partnerships are playing a vital role in bridging this skills gap.

The initial capital expenditure for digital twin solutions can be a barrier for some organizations, particularly small and medium-sized enterprises (SMEs). However, as the technology matures and becomes more accessible, the cost of entry is expected to decrease, making it a more viable option for a broader range of businesses. Government incentives and industry collaborations could further accelerate adoption.

The Future Outlook: Sustaining 25% Operational Savings Post-2025

As U.S. industries progress towards achieving 25% operational savings by 2025 through digital twins, the focus will inevitably shift toward sustaining and even expanding these benefits beyond the initial target. The long-term outlook for digital twin technology involves continuous innovation, integration with emerging technologies, and a deeper embedment into organizational strategies. This forward-looking perspective is critical for maximizing enduring value.

The evolution of artificial intelligence (AI) and machine learning (ML) will further enhance the capabilities of digital twins, allowing for even more sophisticated predictive analytics and autonomous decision-making. The convergence of digital twins with technologies like the Internet of Things (IoT), augmented reality (AR), and blockchain promises to create highly intelligent and interconnected operational environments.

Evolution of digital twin capabilities

- AI-Driven Insights: Leveraging AI for more accurate predictions and automated optimization.

- Interoperability: Greater integration with other enterprise systems and external data sources.

- Scalability: Easier deployment and management of digital twins across large-scale operations.

- Human-Machine Collaboration: Enhanced interfaces for human operators to interact with and derive insights from digital twins.

The journey towards full digital transformation is ongoing, and digital twins are a cornerstone of this evolution. Their ability to provide a comprehensive, real-time view of operations will continue to drive efficiency, foster innovation, and secure a competitive edge for U.S. industries well beyond 2025, solidifying the importance of digital twin operational savings.

Key Aspect |

Brief Description |

|---|---|

25% Savings Target |

Digital twins projected to achieve significant operational cost reductions for U.S. industries by 2025. |

Virtual Prototyping |

Core method driving savings by reducing physical development cycles and costs. |

Financial Impact |

Broad benefits across manufacturing, aerospace, energy, and healthcare sectors. |

Future Outlook |

Continued growth and integration with AI/ML to sustain and expand benefits post-2025. |

Frequently Asked Questions About Digital Twin Operational Savings

Digital twins are virtual replicas of physical assets or processes. They save money by enabling virtual prototyping, predictive maintenance, and process optimization, reducing the need for costly physical iterations and preventing unexpected downtime.

Manufacturing, aerospace, energy, and healthcare are among the primary beneficiaries. These sectors leverage digital twins for optimizing production, enhancing product development, improving asset management, and streamlining complex operations.

Virtual prototyping allows companies to design, test, and refine products or processes entirely in a digital environment. This significantly reduces costs associated with physical prototypes, materials, labor, and time-to-market, directly contributing to the savings target.

Key challenges include complex data integration, cybersecurity risks, a shortage of skilled professionals, and the initial investment required. Addressing these requires strategic planning, robust security protocols, and talent development.

Yes, the benefits are expected to grow. Future advancements in AI, machine learning, and integration with other emerging technologies will further enhance digital twin capabilities, leading to sustained and expanded operational savings and efficiencies.

Impact and Implications

The drive towards digital twin operational savings is not merely a short-term goal but a fundamental shift in industrial strategy. The projected 25% savings by 2025 underscores the immediate financial imperative and the long-term competitive advantage this technology offers. As U.S. industries increasingly integrate digital twins, observers should monitor how these savings translate into market leadership, innovation capacity, and overall economic resilience. The evolving landscape of interconnected digital and physical assets will define the next era of industrial productivity and efficiency.